TECNO ALFA

CUSTOMISED

CHECK VALVES

TECNO ALFA

CUSTOMISED

CHECK VALVES

Production Phases

Production Phases

COMPLETELY MADE IN Tecno Alfa

COMPLETELY MADE IN Tecno Alfa

Tecno Alfa S.r.l. manufactures check valves, flow limiters, by-passes and technical items for the heat and hydro sanitary industry. Each product undergoes a strict inspection and is tested using highly specialised machinery that allow Tecno Alfa S.r.l. to provide customers with quality products.

Tecno Alfa S.r.l. has the opportunity to change certain parameters of its machinery in order to perform specific tests or to customise the product upon request.

Tecno Alfa S.r.l. manufactures check valves, flow limiters, by-passes and technical items for the heat and hydro sanitary industry. Each product undergoes a strict inspection and is tested using highly specialised machinery that allow Tecno Alfa S.r.l. to provide customers with quality products.

Tecno Alfa S.r.l. has the opportunity to change certain parameters of its machinery in order to perform specific tests or to customise the product upon request.

DESIGN

Realisation of 3D drawings based on predetermined targets.

PROTOTYPING

Before moulding, we carefully verify the main requirements and, if needed, we make changes in order to obtain proper functioning.

FUNCTIONALITY TEST

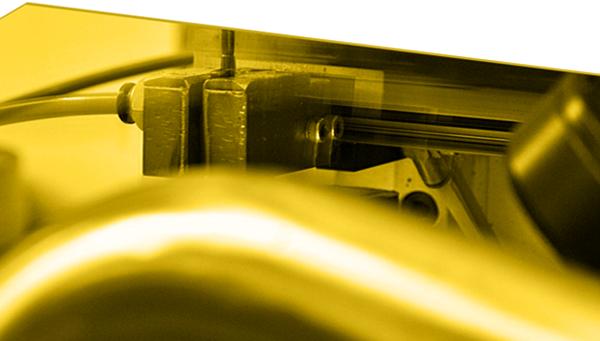

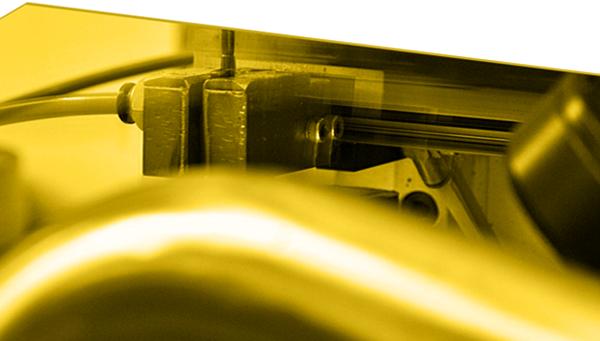

We test the flow rate and the correct functioning of the valves with a certified test bench.

REALISATION OF MOULDS

Creation of moulds through 3D drawings.

MOULDING

After the moulds have been completed, we turn raw material into the product by using an injection moulding press.

DIMENSIONAL CONTROL

Through a profile reader, we measure every single component of the valve and of the equipment to verify that sizes are correct.

ASSEMBLY

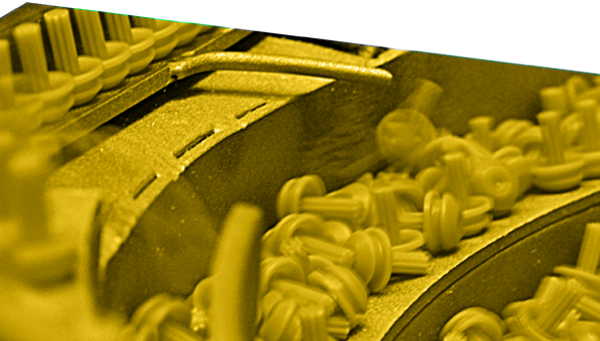

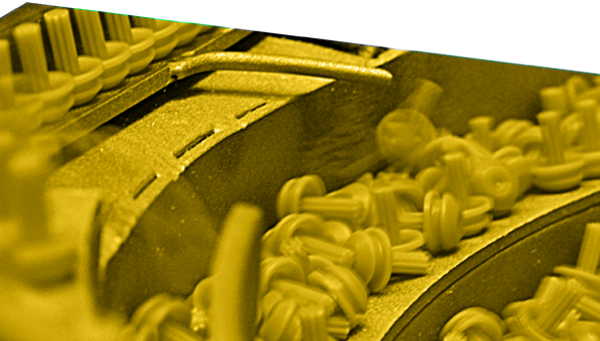

Before the final assembly, the O-rings are put together and checked by automatic machines.

TESTING

Using a certified control system, we check the product and make sure that the functionality of the shutter and the hold of the valve in counter pressure are 100% effective.

VISUAL CONTROL

With the support of 4 cameras, we perform a 360-degree check on every single product, eliminating possible defects that might have occurred during the assembly phase and identifying each model.

WEIGHING AND PACKAGING

Once finished, the product is weighed using a counting scale, packed with its identification details and it is ready to be shipped.

DESIGN

Realisation of 3D drawings based on predetermined targets.

PROTOTYPING

Before moulding, we carefully verify the main requirements and, if needed, we make changes in order to obtain proper functioning.

FUNCTIONALITY TEST

We test the flow rate and the correct functioning of the valves with a certified test bench.

REALISATION OF MOULDS

Creation of moulds through 3D drawings.

MOULDING

After the moulds have been completed, we turn raw material into the product by using an injection moulding press.

DIMENSIONAL CONTROL

Through a profile reader, we measure every single component of the valve and of the equipment to verify that sizes are correct.

ASSEMBLY

Before the final assembly, the O-rings are put together and checked by automatic machines.

TESTING

Using a certified control system, we check the product and make sure that the functionality of the shutter and the hold of the valve in counter pressure are 100% effective.

VISUAL CONTROL

With the support of 4 cameras, we perform a 360-degree check on every single product, eliminating possible defects that might have occurred during the assembly phase and identifying each model.

WEIGHING AND PACKAGING

Once finished, the product is weighed using a counting scale, packed with its identification details and it is ready to be shipped.